Why the EV battery circular economy is key for sustainability

Electric vehicles (EVs) are changing the conversation around our carbon footprints, offering a future without tailpipe emissions. Yet, concerns around EV production emissions vs. ICE vehicles leave many asking: are EV batteries sustainable?

The answer is, yes, if we approach the conversation with an EV battery circular economy mindset. Battery repair, remanufacturing, recycling and repurposing services now mean that every battery can deliver on its full sustainability potential. Let’s break this down.

Discover more content...

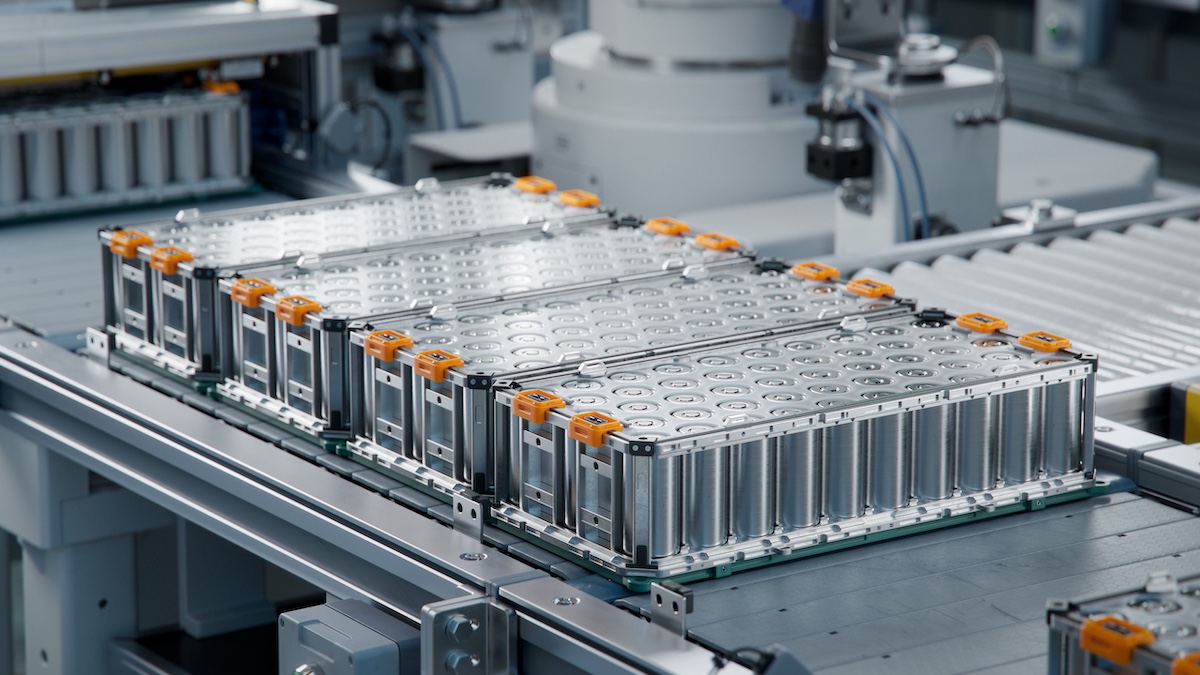

Are EV batteries sustainable? Production emissions vs lifetime impact

There’s no denying that EV production emissions are higher compared to other fuel types, with reports from Argonne National Laboratory, highlighting a 60% increase for electric vehicles vs. ICE vehicles. This is largely due to battery manufacturing, which is much more complex, requires more mining of raw materials, and has less developed supply chains.

However, this increased energy consumption at production stage is causing a common misconception around EV battery sustainability overall – with many suggesting it’s not what it seems.

The reality? Approximately half of an EV battery’s lifecycle emissions are generated during manufacturing process, and data shows these production emissions are offset within two years of driving an EV. Regions with cleaner electricity grids like Norway and France, show an even shorter offset period – something that is expected to replicate in other regions as grid technology advances.

So, while EV production emissions are higher, it’s important to look at the vehicle’s entire lifecycle emissions to understand their true environmental impact. According to a 2024 report from the International Energy Agency (IEA), EVs have been proven to produce 50% less lifecycle emissions than ICE vehicles over 15 years (or approximately 124,000 miles). It’s also worth noting that EV technology is still being developed, and as new advances come to market, emission savings are predicted to improve further in the near future.

Introducing the EV battery circular economy

EV battery sustainability doesn’t end with driving emissions. To truly minimise environmental impact, we must ensure these vehicles are on the road for as long as possible – something that many consumers have concerns about due to battery degradation misconceptions.

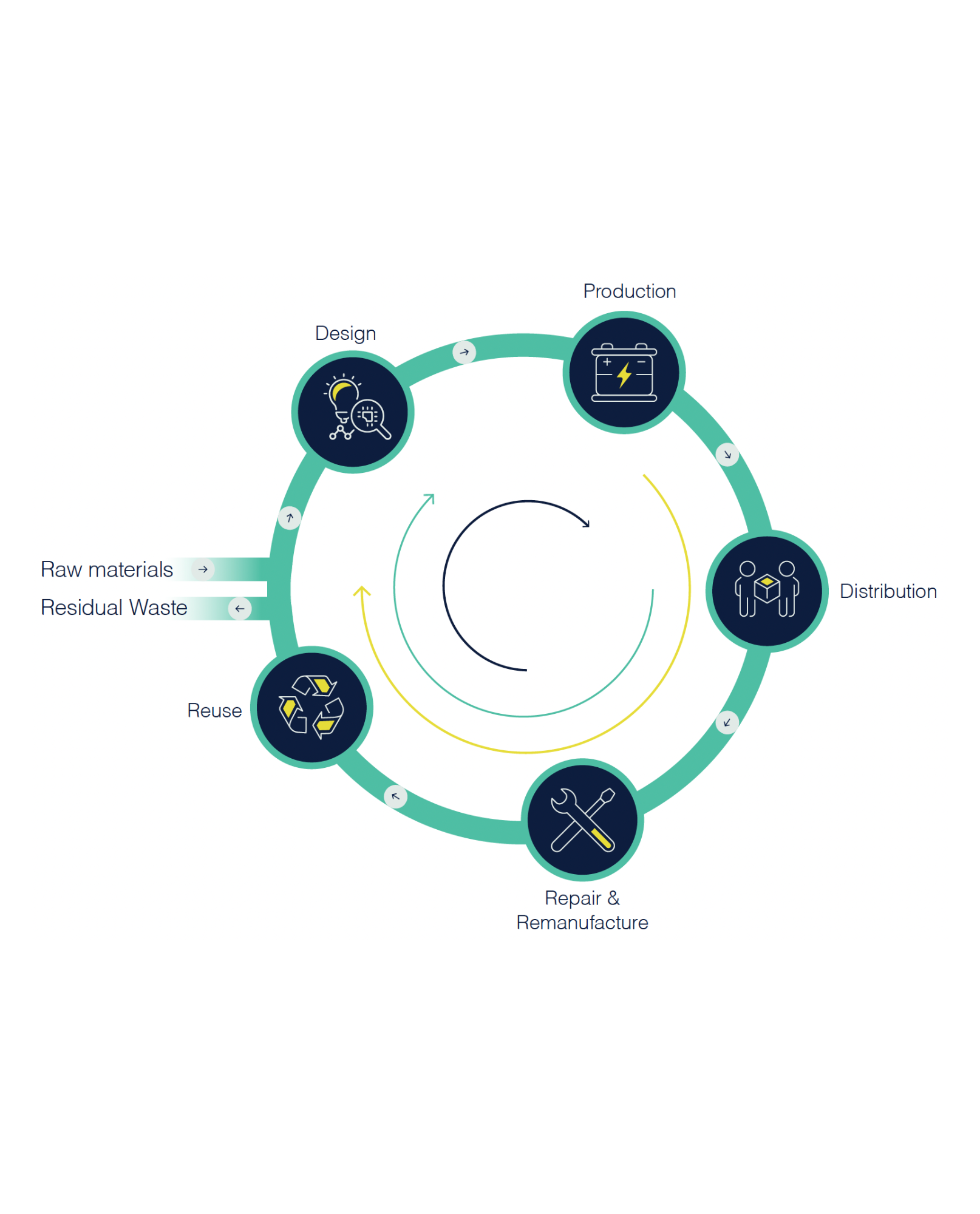

By building a circular EV battery economy (shown in the diagram below), we can extend battery life through repair, remanufacturing, recycling and reuse. Reducing the rate in which materials are discarded and supporting a more responsible supply chain.

In doing so, we can maximise the materials already in the ecosystem. Reducing the need for more raw materials, lowering the carbon footprint of battery production over time and ensuring EV battery sustainability reaches its full potential.

EV battery repairs and remanufacturing: extending the life of every battery

As EV battery technology evolves, so too does our ability to repair and maintain them – a vital step in driving long-term sustainability. Like most technologies, batteries degrade over time and, in rare cases, develop faults. However, that doesn’t mean they need to be discarded right away.

In most instances, the battery issue lies with a single component which can be identified by advanced diagnostic tests and then repaired by expert technicians.

Remanufacturing takes this one step further, replacing worn materials and rebalancing the battery management system to restore the pack to the original, or better, condition.

Not only does this delay the need for recycling – an expensive and complex process still in its infancy – but it gives confidence to EV drivers that they can treat their faulty EV in a similar way to an ICE vehicle.

Benefits of EV battery repairs and remanufacturing:

- Addresses consumer concerns around EV battery sustainability

- Gives consumer confidence in the servicing capabilities for EVs

- Keeps the battery performing for longer

- Maximises the use of raw materials already in the ecosystem

Next life: EV battery repurposing

If a battery repair is not suitable or viable, the pack can enter the next stage of the EV battery circular economy: repurposing. At EV Battery Solutions, this consists of using diagnostic insights to make responsible recommendations on the next step. While this can sometimes mean recycling, should the battery have reached the end of its life, in many cases, battery components can be repurposed for other uses, like supporting local energy grids and home energy storage systems.

EV battery repurposing is a particularly exciting stage of the circular model, demonstrating that as battery volumes grow, so does the opportunity for a cleaner future, on and off the road.

Why EV battery repurposing is important:

- Reuses existing battery components

- Drives carbon neutrality and energy independence

- Extends the use of raw materials after their original purpose, reducing the need for mining

- Reduces unnecessary waste and energy needed to recycle

Closing the loop with recycling

Even the most robust EV batteries reach a point where they can’t be repaired, remanufactured or repurposed. At this stage, safe and sustainable recycling is an essential step for sustainability.

For most EV battery variants, the majority of the pack can be recycled, keeping vital raw materials in the ecosystem and reducing the need for mining. But, it’s an energy intensive process that is most suitable after other options have been exhausted.

The journey to net zero doesn’t end with getting EVs on the road. To truly achieve sustainability, we must better manage the resources in the battery.

While the industry works to lower EV production emissions and further decrease an electric vehicle’s lifetime carbon footprint, an EV battery circular economy can be achieved now.

At EV Battery Solutions, our advanced infrastructure, engineering excellence and data-led operations are helping our manufacturer and fleet partners to shape a cleaner future.

Talk to our team today to explore how we can support your battery repair and remanufacturing objectives.

Let's take charge of the future, together

We’re transforming the in-life battery operations of the world’s leading automotive manufacturers. Get in touch to find out how.